Future-Proofing Timber Frame Homes with Superglass

Published on September 21, 2025

Posted in Advice & Reviews

by MKM

4 minutes min read

Future-Proofing Timber Frame Homes: Superglass Insulation and the Future Homes Standard 2025

As England moves towards the Future Homes Standard (FHS) 2025, timber frame construction is proving to be a smart choice for building energy-efficient, low-carbon homes. Its design flexibility and fast build times make it well suited to the FHS’s goals. When combined with Superglass insulation, it helps delivers the performance, sustainability, and compliance developers and builders need to stay ahead.

What Is the Future Homes Standard?

The Future Homes Standard (FHS) 2025 is a government initiative aimed at significantly reducing carbon emissions from new homes in England. It will become mandatory from 2025, and its core goal is to ensure that new homes produce 75–80% less carbon emissions than those built under current building regulations.

Why Timber Frame Construction?

- It has lower embodied carbon than steel or concrete, helping reduce the overall carbon footprint of construction.

- Design flexibility – Suitable for off-site and on-site construction.

Superglass Insulation: The Ideal Partner for Timber Frame

Superglass offers a range of glass mineral wool insulation products specifically designed for timber frame applications. Among these, is their new multi-application product Adapt Slab 35, Thanks to its versatility, Adapt Slab 35 is an ideal choice for a wide variety of timber frame construction types.

Below are typical constructions using Superglass Adapt Slab 35 which meets the Future Homes Standard Fabric u-values for timber frame walls, roofs and floors.

External Timber Frame Walls

U-value achieved = 0.15W/m²K

|

Build-up |

Thermal Conductivity (W/mK) |

Thermal Resistance (m²K/W) |

|

102.5mm Outer leaf Brickwork |

0.77 |

|

|

50mm Unvented low emissivity cavity |

|

0.77 |

|

Reflective Breather Membrane |

|

|

|

9mm Oriented Strandboard (OSB) |

0.13 |

|

|

140mm Superglass Adapt Slab 35 between timber studs* |

0.035 |

|

|

Reflective Vapour Control Layer (VCL) |

|

|

|

25mm Unvented low emissivity cavity between timber battens/service void** |

|

0.78 |

|

52.5mm Siniat Thermal PIR Insulated Plasterboard |

|

1.89 |

*Timber bridging assumed at 15% at 600mm centres. Bridge thermal conductivity of 0.13W/mK.

** Timber bridging assumed at 9% at 600mm centres. Bridge thermal conductivity of 0.13W/mK.

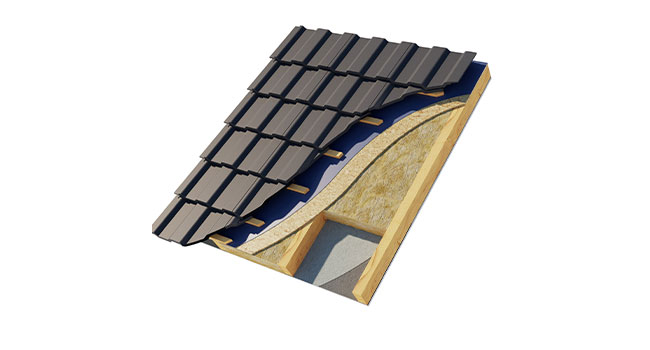

Warm Pitched Roofs

U-value achieved = 0.11W/m²K

|

Build-up |

Thermal Conductivity (W/mK) |

Thermal Resistance (m²K/W) |

|

Roof Tiles |

|

|

|

50mm well vented cavity between timber battens and counter battens |

|

|

|

Standard Breather Membrane |

|

|

|

230mm Superglass Adapt Slab 35 (90+140mm) between timber rafters* |

0.035 |

|

|

Reflective Vapour Control Layer (VCL) |

|

|

|

25mm Unvented low emissivity cavity between timber battens/service void** |

|

0.78 |

|

72.5mm Siniat Thermal PIR Insulated Plasterboard |

|

2.79 |

*Timber bridging assumed at 9% at 600mm centres. Bridge thermal conductivity of 0.13W/mK.

** Timber bridging assumed at 9% at 600mm centres. Bridge thermal conductivity of 0.13W/mK.

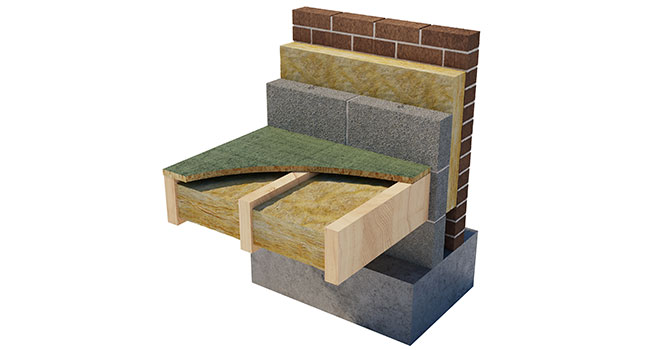

Suspended Timber Ground Floors

U-value Achieved = 0.12W/m²K

|

Build-up |

Thermal Conductivity (W/mK) |

|

22mm Chipboard Flooring |

0.13 |

|

Vapour Control Layer (VCL) |

|

|

200mm Superglass Adapt Slab 35 (2x100mm) between timber joists* |

0.035 |

P/A Ratio = 0.10

*Timber bridging assumed at 11% at 600mm centres. Bridge thermal conductivity of 0.13W/mK.

The Future Homes Standard 2025 is setting new expectations for how homes are built across England. By choosing timber frame construction alongside Superglass insulation, developers can deliver homes that not only comply with the latest regulations but are also ready for a low-carbon future. Whether it’s a single plot or a large development, Superglass gives you the performance, sustainability, and technical support you need to meet the standard, and go beyond it.

Find out more about Superglass.